The Spiderwick Chronicles Field Guide: A Comprehensive Overview

Delve into the enchanting world of faeries with this elaborate volume, revealing 14 core creatures and an astounding 15 additional ones, alongside journal entries․

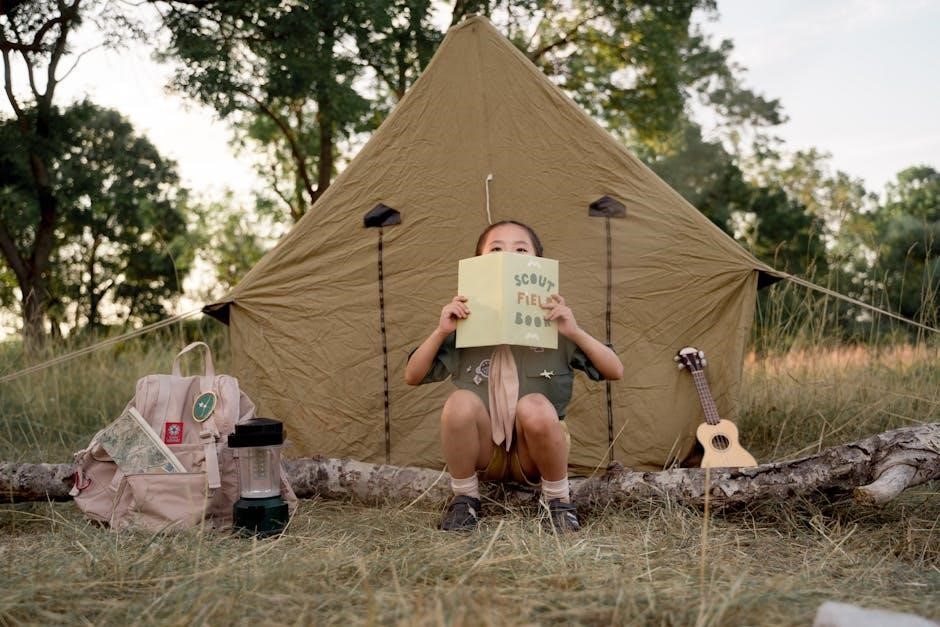

The Spiderwick Chronicles Field Guide isn’t merely a companion to the beloved series; it’s a foundational artifact within the narrative itself․ Discovered by the Grace children – Jared, Simon, and Mallory – within the dusty attic of their great-aunt Lucinda’s dilapidated Victorian home, the Guide serves as the initial key unlocking the hidden world of faerie․ This mysterious, handmade book, penned by the enigmatic Arthur Spiderwick, details the creatures inhabiting a realm coexisting alongside our own, a realm previously unknown to the siblings․

More than just a bestiary, the Field Guide is presented as a genuine, in-universe document․ It’s filled with Arthur Spiderwick’s meticulous observations, sketches, and warnings about the often-dangerous inhabitants of the faerie world․ The book’s discovery immediately plunges the children into a thrilling adventure, forcing them to confront the reality of magical beings and the secrets hidden within their new home․ It’s the catalyst for everything that follows in The Spiderwick Chronicles․

The Origins of the Spiderwick Family

The Spiderwick family history is intrinsically linked to the Field Guide and their long-standing, though often obscured, involvement with the faerie world․ Arthur Spiderwick, the author of the Guide, wasn’t simply a naturalist; he was a dedicated researcher obsessed with documenting the hidden realm of faeries․ His family, for generations, possessed a unique awareness of these creatures, a knowledge passed down through careful observation and meticulous record-keeping․

However, this knowledge came at a cost․ The Spiderwick family faced challenges and dangers stemming from their interactions with faeries, leading to a deliberate attempt to conceal their research and protect future generations․ The Field Guide itself represents the culmination of this family legacy, a testament to their dedication and a warning about the perils of the faerie world․ The Grace children’s discovery of the Guide reawakens this dormant family history, drawing them into a conflict that has spanned generations․

Arthur Spiderwick and His Research

Arthur Spiderwick’s relentless pursuit of knowledge regarding faeries drove the creation of the Field Guide․ He wasn’t a fanciful storyteller, but a dedicated observer, meticulously documenting the creatures he encountered․ His research wasn’t born from mere curiosity; it stemmed from a deep-seated belief in the reality of the faerie world and a desire to understand its rules and inhabitants․

The Field Guide represents the culmination of years spent studying faeries, filled with detailed descriptions, behavioral patterns, and cautionary notes․ His journal entries, included within the book, offer a personal glimpse into his investigations and the challenges he faced․ Spiderwick’s work wasn’t widely accepted during his time, leading him to conceal his findings, hoping future generations might benefit from his research – a hope realized with the Grace children’s discovery․

Creatures Featured in the Field Guide

Explore a diverse bestiary, showcasing fourteen core faerie species, plus fifteen additional wonders like mermaids and gargoyles, detailed within the Guide’s pages․

Core 14 Creatures from the Chronicles

The heart of the Spiderwick Chronicles Field Guide lies in its detailed examination of the fourteen creatures central to the initial narrative․ These beings, pivotal to Jared, Simon, and Mallory’s adventures, are meticulously documented with illustrations and comprehensive descriptions․ Readers encounter the mischievous Brownies, helpful but demanding household spirits, and the dangerous Redcaps, goblin-like creatures known for their crimson-stained caps and violent tendencies․

Further exploration reveals the Grims, protective but fearsome guardians, and the Sylphs, ethereal beings connected to the wind․ The Field Guide doesn’t shy away from more unsettling creatures like the Sprites, often depicted as tricksters, and the Nymphs, beautiful but potentially dangerous water spirits․ Other core inhabitants include the Pixies, the Hobgoblins, and various types of Goblins, each possessing unique characteristics and behaviors․ The guide also details the Boggarts, the Trulls, and the Lethargiles, completing the foundational bestiary of the Spiderwick world․ Understanding these fourteen is crucial to grasping the full scope of the faerie realm․

Additional 15 Creatures – Expanding the Faerie World

Beyond the initial fourteen, the Field Guide unveils a further fifteen creatures, significantly broadening the scope of the faerie world presented in the Spiderwick Chronicles․ This expansion demonstrates the sheer diversity and complexity of the hidden realm coexisting with our own․ Among these additions, the enchanting Mermaids are detailed, showcasing their lore and unique depictions within the Spiderwick universe․

Equally fascinating are the Gargoyles, presented not merely as stone ornaments, but as vigilant guardians with a rich history․ The guide also introduces lesser-known beings, enriching the tapestry of faerie life․ These creatures range from benevolent spirits to potentially dangerous entities, each with specific habitats and behaviors․ This extended bestiary provides a deeper understanding of the intricate ecosystem of faeries, offering readers a more complete and immersive experience within the Spiderwick world, and solidifying the guide’s value as a comprehensive resource․

Mermaids: Lore and Depiction

The Spiderwick Chronicles Field Guide doesn’t present mermaids as the benevolent figures of traditional folklore․ Instead, DiTerlizzi’s illustrations and accompanying text reveal a more complex and potentially dangerous depiction of these aquatic faeries․ The guide delves into their unique lore, portraying them as creatures deeply connected to waterways, possessing alluring yet deceptive qualities․

Unlike the romanticized versions, these mermaids are described with a hint of menace, their beauty masking a wild and unpredictable nature․ The Field Guide details their specific habitats – often secluded pools and rivers – and hints at their interactions with other fae beings․ Their depiction emphasizes a primal connection to the water, and a guarded existence away from human interference․ This nuanced portrayal adds depth to the faerie world, showcasing that not all creatures are friendly, and caution is paramount when venturing into their domain․

Gargoyles: Guardians and Stone Sentinels

Within the pages of the Spiderwick Chronicles Field Guide, gargoyles are presented not merely as architectural ornaments, but as living, breathing guardians deeply rooted in faerie lore․ DiTerlizzi’s artistic vision brings these stone sentinels to life, showcasing their imposing forms and watchful presence․ The guide details their historical role as protectors, often bound to specific locations – churches, castles, and old mansions – to ward off malicious spirits․

These aren’t simply statues that come alive at night; they possess a unique sentience and a connection to the earth itself․ The Field Guide explores their inherent magical abilities, including the power to observe unseen and to subtly influence events․ Their stoic nature and enduring patience are highlighted, emphasizing their long-lived existence and dedication to their protective duties․ Encountering a gargoyle, according to the guide, is a sign of powerful magical activity nearby․

The Field Guide’s Structure and Content

The guide blends Arthur Spiderwick’s journal entries, detailed creature descriptions, and stunning illustrations, creating a comprehensive and immersive exploration of the faerie world․

Arthur Spiderwick’s Journal Entries

Scattered throughout the Spiderwick Chronicles Field Guide are fascinating snippets directly from Arthur Spiderwick’s personal journal․ These aren’t merely add-ons; they are integral to understanding the guide’s origins and its direct connection to the events unfolding in the initial Spiderwick Chronicles book․

These journal entries offer a unique, first-person perspective, providing insights into Arthur’s research methods, his encounters with various faeries, and the challenges he faced while compiling his knowledge․ They lend an air of authenticity and immediacy to the guide, making the fantastical creatures feel more real and the faerie world more accessible․

Furthermore, these entries aren’t simply descriptive; they often hint at deeper mysteries and foreshadow future events within the series, rewarding attentive readers with a richer understanding of the overarching narrative․ They also serve as a crucial link, explicitly tying the field guide to the experiences of the Grace children, Jared, Simon, and Mallory․

Illustrations and Artistic Style

Tony DiTerlizzi’s illustrations are absolutely central to the immersive experience of the Spiderwick Chronicles Field Guide․ His artistic style isn’t simply about depicting the creatures; it’s about presenting them as if they were genuinely documented specimens within a naturalist’s field guide․ The illustrations possess a wonderfully aged, hand-drawn quality, mimicking the look of antique botanical or zoological illustrations․

DiTerlizzi masterfully employs watercolor and ink, creating a delicate yet detailed aesthetic․ The creatures aren’t overly fantastical or cartoonish; instead, they feel grounded and believable, enhancing the sense of realism within the faerie world․ Marginalia, sketches, and annotations further contribute to the impression of a working document, meticulously compiled over time․

This distinctive style, honed through previous works like The Spider & the Fly, perfectly complements Holly Black’s writing, creating a cohesive and captivating world for readers to explore․

Detailed Creature Descriptions

The Spiderwick Chronicles Field Guide doesn’t merely name the faeries; it provides exhaustive descriptions, presented as meticulous observations from Arthur Spiderwick himself․ Each creature entry details its physical characteristics – size, coloration, distinguishing features – alongside information about its habitat, diet, and typical behaviors․

These aren’t simple monster entries; they read like genuine scientific reports․ Spiderwick notes vulnerabilities, potential dangers, and even folklore associated with each creature․ The descriptions often include warnings about interacting with these beings, emphasizing their unpredictable and sometimes malicious nature․

Crucially, the guide categorizes creatures, hinting at a complex faerie taxonomy․ This level of detail elevates the world-building, making the faerie realm feel vast, ancient, and governed by its own intricate rules․ The descriptions are integral to understanding the lore․

Classification of Faeries

Arthur Spiderwick’s Field Guide doesn’t present faeries as a homogenous group; instead, it suggests a complex and hierarchical classification system․ While not explicitly laid out as a rigid taxonomy, the guide subtly categorizes creatures based on their nature, power, and alignment – hinting at a deeper organizational structure within the faerie world․

Certain creatures are deemed more dangerous or powerful than others, implicitly establishing a ranking․ The guide differentiates between solitary faeries and those that exist in colonies or hierarchies, suggesting social structures․ Furthermore, distinctions are made between benevolent, neutral, and malevolent fae, influencing how one should approach them․

This classification isn’t always clear-cut, adding to the mystery and danger․ Spiderwick’s notes often acknowledge exceptions and variations, reinforcing the idea that the faerie realm is a wild and unpredictable place․

Behavioral Patterns of Faeries

The Spiderwick Field Guide details that faeries aren’t governed by human logic or morality, exhibiting behaviors often described as capricious and unpredictable․ Many are intensely territorial, fiercely guarding their domains and reacting aggressively to intrusions․ Others are mischievous, delighting in playing pranks and leading humans astray․

Spiderwick’s observations reveal a strong connection between faerie behavior and the natural world; their actions often mirroring seasonal changes or responding to environmental disturbances․ Certain creatures are nocturnal, while others are active only during specific weather conditions․ The guide also notes a tendency for faeries to operate under ancient rules and traditions, often incomprehensible to humans․

Crucially, the Field Guide emphasizes the importance of respect when interacting with fae, warning against offense or attempts to control them, as this can provoke dangerous consequences․

The Field Guide’s Role in the Spiderwick Universe

This guide isn’t merely a compendium; it directly fuels the narrative, connecting to the first book and featuring character cameos, acting as a vital device․

Connecting the Guide to the First Book

The Spiderwick Chronicles truly begins with the discovery of Arthur Spiderwick’s Field Guide within the dusty attic of the old Victorian house․ This isn’t just a plot device; the guide is the catalyst for the entire adventure experienced by Jared, Simon, and Mallory Grace․ The siblings stumble upon a world hidden in plain sight, a world of faeries and fantastical creatures, all because of the knowledge contained within those aged pages․

Dozens of snippets from Arthur Spiderwick’s personal journal are included, directly linking the information within the guide to the events unfolding in the first book․ These entries aren’t simply supplemental; they provide crucial context, warnings, and insights into the behaviors of the creatures the children encounter․ The guide isn’t a passive object; it actively shapes their understanding and survival in this newly revealed realm, making it integral to the story’s progression and the unfolding mysteries․

Character Cameos and Interactions

Beyond the detailed creature descriptions and Arthur Spiderwick’s journal entries, the Field Guide offers delightful glimpses into the wider Spiderwick Chronicles universe through unexpected character cameos․ Readers aren’t simply presented with information; they’re treated to brief interactions and appearances from familiar faces, enriching the overall narrative experience and hinting at larger storylines․

These cameos serve as a clever narrative device, reinforcing the interconnectedness of the world and providing subtle clues about the characters’ motivations and histories․ It’s a rewarding experience for those already invested in the series, offering a deeper understanding of the relationships and events beyond the main plot․ The inclusion of these moments elevates the Field Guide from a mere bestiary to a vital piece of the Spiderwick lore, fostering a stronger connection between the book and its readers․

The Guide as a Narrative Device

The Spiderwick Chronicles Field Guide transcends the typical reference book format, functioning as a crucial narrative device within the larger series․ Presented as Arthur Spiderwick’s personal journal and research, it isn’t merely about the faerie world; it is a window into it, offering a unique perspective shaped by a dedicated observer․ This framing device immediately establishes authenticity and immerses the reader in the mystery surrounding the Spiderwick family․

The Guide’s structure, with its handwritten notes and detailed illustrations, mimics a genuine field journal, enhancing the sense of discovery․ It’s through this artifact that the Grace children – Jared, Simon, and Mallory – unravel the secrets of the faerie world, making the Guide integral to their journey and the unfolding plot․ It’s not just a companion to the story; it is part of the story itself․

Impact and Legacy

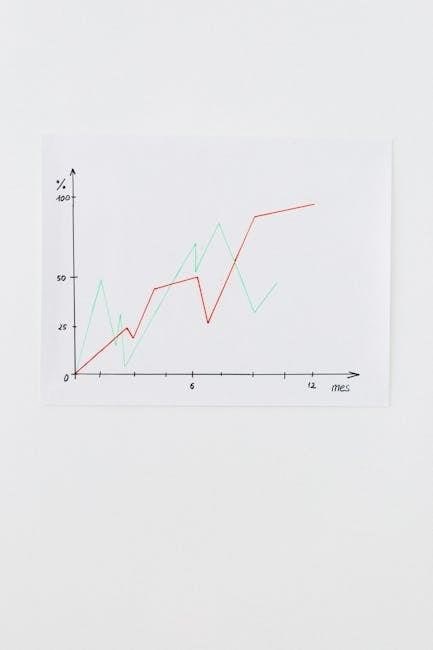

The Spiderwick Chronicles, including the Field Guide, achieved immense popularity, selling over 20 million copies and being translated into thirty countries worldwide․

Sales and Popularity of the Spiderwick Chronicles

The Spiderwick Chronicles, spearheaded by the captivating Field Guide, rapidly ascended to become a phenomenal success in children’s literature․ The series, a collaboration between Tony DiTerlizzi and Holly Black, has impressively sold over 20 million copies globally, demonstrating its widespread appeal to young readers and families alike․ This remarkable figure underscores the enduring fascination with the fantastical world of faeries presented within the books․

Beyond sheer sales numbers, the series garnered significant critical acclaim and a devoted fanbase․ The unique blend of adventure, mystery, and folklore resonated deeply with its audience․ The Field Guide, in particular, served as a crucial entry point into this universe, captivating readers with its detailed illustrations and immersive world-building․ Its popularity fueled demand for subsequent books and adaptations, solidifying its place as a modern classic in the realm of fantasy literature․

Adaptations: Film and Beyond

The immense popularity of The Spiderwick Chronicles naturally led to adaptations beyond the printed page․ Most notably, a feature film adaptation was released, bringing the fantastical world and the adventures of the Grace children to a wider audience․ While the film offered a visual interpretation of the story, it served to further amplify the series’ recognition and introduce it to a new generation of fans․

However, the legacy extends beyond the initial film․ Discussions and explorations of potential television series or reboots have surfaced over time, indicating continued interest in revisiting the Spiderwick universe․ The enduring appeal of the Field Guide and the broader series suggests a fertile ground for future adaptations, potentially exploring different facets of the faerie world and expanding upon the original narratives․ The franchise’s adaptability ensures its continued relevance in various media formats․

Translations and Global Reach

The success of The Spiderwick Chronicles wasn’t confined to English-speaking countries; the series achieved remarkable global reach through translations into over thirty countries․ This widespread translation effort demonstrates the universal appeal of the story’s themes – family, courage, and the wonder of the natural world – resonating with readers across diverse cultures․

The ability to experience the adventures of Jared, Simon, and Mallory in their native languages broadened the series’ impact significantly, fostering a global community of fans․ This international reception solidified The Spiderwick Chronicles’ position as a modern classic in children’s literature, proving that captivating storytelling transcends linguistic barriers․ The Field Guide, as a central element, played a key role in this international success, captivating imaginations worldwide․

Tony DiTerlizzi’s Contribution

DiTerlizzi masterfully imbued the series with rich imagination, from picture books to chapter books, and notably co-created The Spiderwick Chronicles with Holly Black․

DiTerlizzi’s Illustrative Style

Tony DiTerlizzi’s artistic approach is central to the immersive quality of The Spiderwick Chronicles and, specifically, the Field Guide․ His illustrations aren’t merely decorative; they function as integral components of the narrative, lending authenticity to the fantastical creatures and environments described within the text․ The style blends detailed realism with a touch of whimsical fantasy, creating images that feel both believable and otherworldly․

He employs a technique reminiscent of classic natural history illustrations, complete with meticulous linework and subtle watercolor washes․ This lends the Field Guide an air of scholarly legitimacy, as if it truly is a document compiled by a dedicated researcher like Arthur Spiderwick․ The creatures aren’t simply drawn; they’re presented as specimens, carefully observed and documented․ This visual style significantly enhances the book’s appeal and contributes to its enduring legacy, captivating readers with its unique blend of artistry and storytelling․

Other Works by Tony DiTerlizzi

Beyond The Spiderwick Chronicles, Tony DiTerlizzi boasts a diverse and celebrated body of work, demonstrating his versatile talent and imaginative storytelling․ He’s known for fanciful picture books like The Spider & the Fly, showcasing his ability to create enchanting worlds for younger audiences․ His contributions extend to chapter book series, notably The Search for WondLa, a captivating adventure that further highlights his rich imagination and world-building skills․

DiTerlizzi consistently imbues his stories with a unique blend of wonder and artistry, establishing a recognizable style across his projects․ His dedication to illustration and narrative craft has earned him widespread acclaim and a devoted readership․ He seamlessly transitions between different formats and age groups, proving his enduring appeal as a children’s book author and illustrator, solidifying his place in the literary landscape․

Collaboration with Holly Black

The phenomenal success of The Spiderwick Chronicles wasn’t a solitary achievement; it was a brilliant collaboration between Tony DiTerlizzi and Holly Black․ Black, a celebrated author of middle-grade and young adult fiction, brought her exceptional storytelling prowess to the project, crafting the compelling narrative and intricate plotlines that captivated readers․ DiTerlizzi, with his masterful illustrations, visually brought Black’s fantastical world to life, creating a truly immersive experience․

Together, they forged a synergistic partnership, resulting in a series that has sold over 20 million copies worldwide․ Their combined talents extended beyond the books themselves, encompassing a feature film adaptation and translations into more than thirty countries․ This enduring partnership demonstrates the power of creative synergy, solidifying their legacy in children’s literature and fantasy storytelling․

Collecting and Identifying Field Guide Editions

First edition copies are highly sought after by collectors, distinguished by specific markings and details; rarity significantly impacts their value within the market․

First Edition Identification

Identifying a true first edition of The Spiderwick Chronicles Field Guide requires careful attention to detail․ Collectors should first examine the copyright page․ A true first edition will explicitly state “First Edition” – though sometimes this is subtly placed․ Look for the complete number line, descending from 10 to 1, indicating a first printing․

The dust jacket is also crucial․ Early printings often feature specific jacket designs, and any subsequent printings may have slight variations․ Pay close attention to any promotional stickers or markings on the jacket, as these can sometimes indicate later printings․ The book’s binding and overall condition are also important factors, with pristine copies commanding higher prices․

Furthermore, researching known printing errors or unique characteristics of the first edition can aid in authentication․ Online collector communities and resources dedicated to The Spiderwick Chronicles can provide valuable insights and verification assistance․ Careful scrutiny and comparison with documented first editions are essential for accurate identification․

Rarity and Value

The value of The Spiderwick Chronicles Field Guide varies significantly based on condition, edition, and demand․ First editions in pristine condition, with intact dust jackets and complete number lines, command the highest prices, often reaching hundreds of dollars․ Signed copies by Tony DiTerlizzi or Holly Black are particularly sought after, increasing their value exponentially․

Rarity is influenced by printing quantities and the book’s overall popularity․ While the series enjoyed substantial sales – exceeding 20 million copies – truly exceptional copies are becoming increasingly scarce․ Condition plays a pivotal role; even a first edition with significant wear or damage will be worth considerably less․

Market trends and collector interest also impact value․ Monitoring auction results and online marketplaces provides insights into current pricing․ Overall, the Field Guide remains a desirable collectible within the fantasy literature genre, appealing to both long-time fans and new collectors alike․